With the new features delivered in Calcium, the latest release of our HRC Software solutions, warehouse operations under SAP EWM gain in reliability, speed and ergonomics, with a single objective in mind: optimising what really matters for frontline logistics teams.

Designed to address the day-to-day needs of warehousing operations, Calcium introduces enhancements that secure barcode scanning, accelerate preparation and packing tasks, and give operators even more flexibility in executing EWM activities.

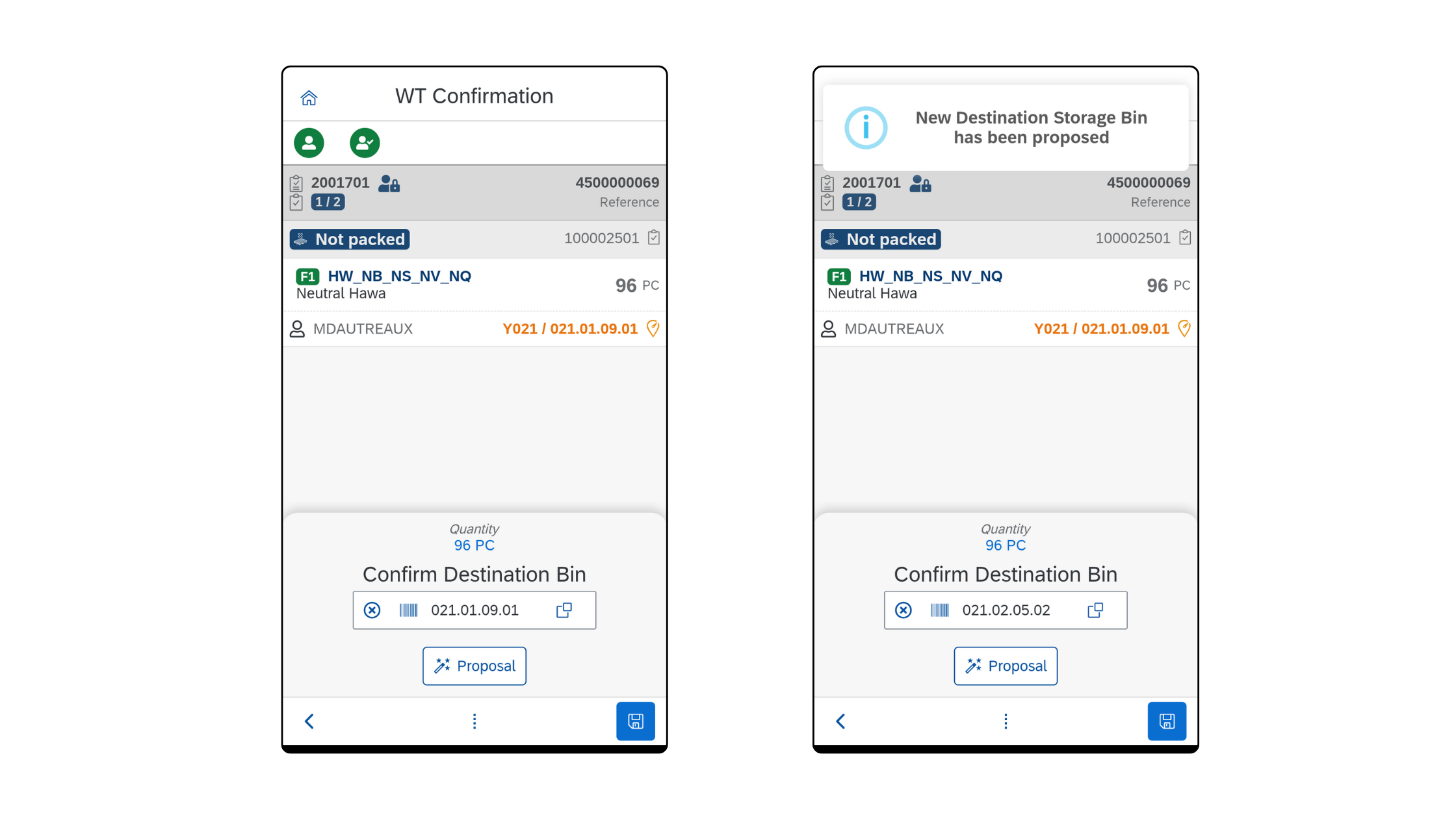

“Next optimal bin”: smart putaway to avoid operational dead-ends

During putaway task confirmation, if the destination bin determined by SAP is not reachable or not suitable (saturated zone, temporary unavailability, layout change), Calcium introduces a simple and highly effective option:- Request the next optimal bin according to the configured putaway strategy.

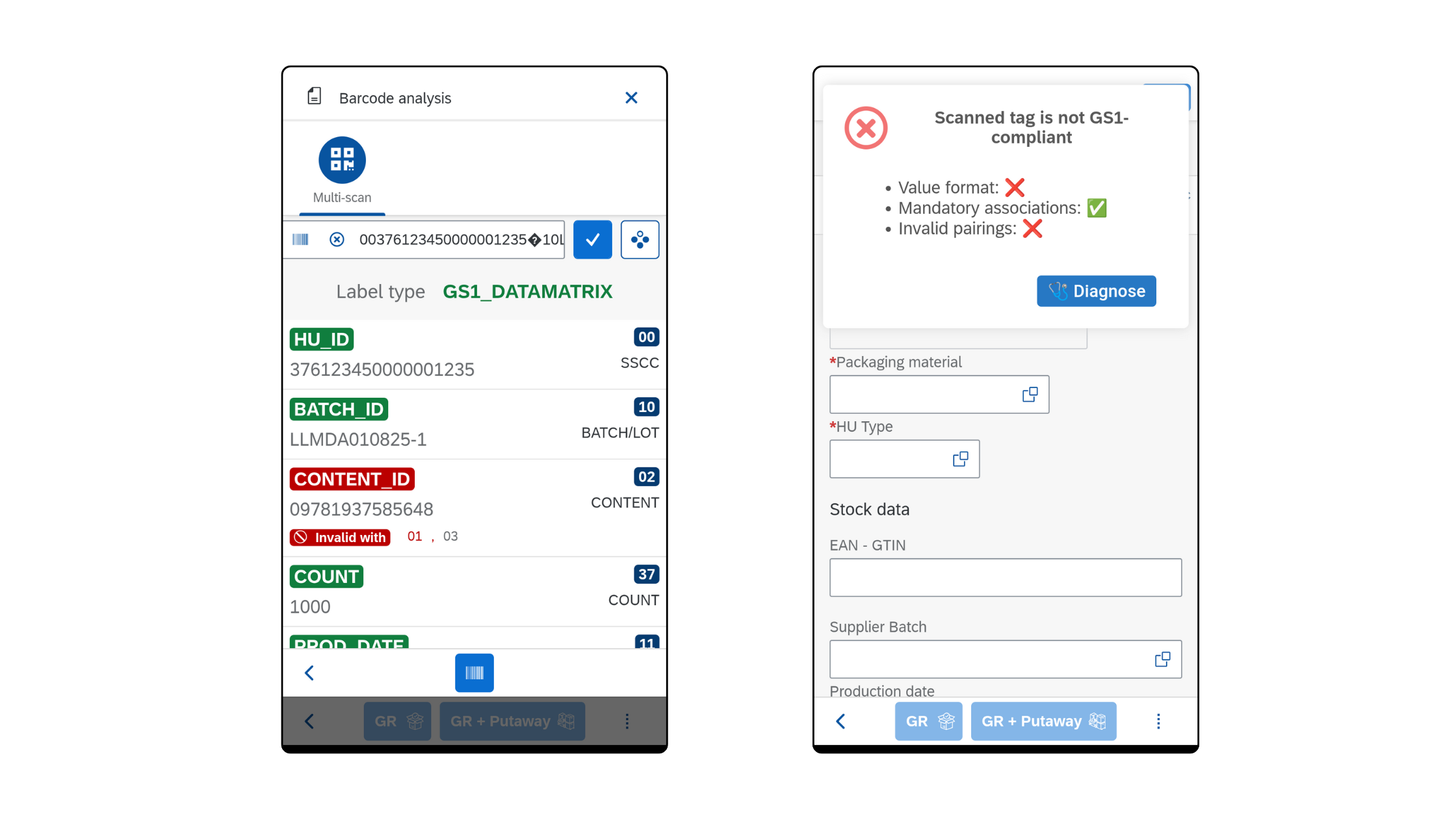

Native GS1 compliance check: safer scans, more reliable operations

GS1 barcodes (1D and 2D) can contain multiple critical pieces of information such as GTIN, batch number, expiry date and serial number. Calcium now natively checks whether the scanned barcode complies with the GS1 standard.

- If the label is compliant, the task continues as normal.

- If it is not compliant, the operator is notified immediately.

This results in less time spent troubleshooting inconsistencies, better escalation to supply chain partners or internal IT, and secured traceability from the very first scan.

Continuous improvement: everyday gains across multiple applications

Calcium also delivers several high-impact enhancements across key warehouse applications.

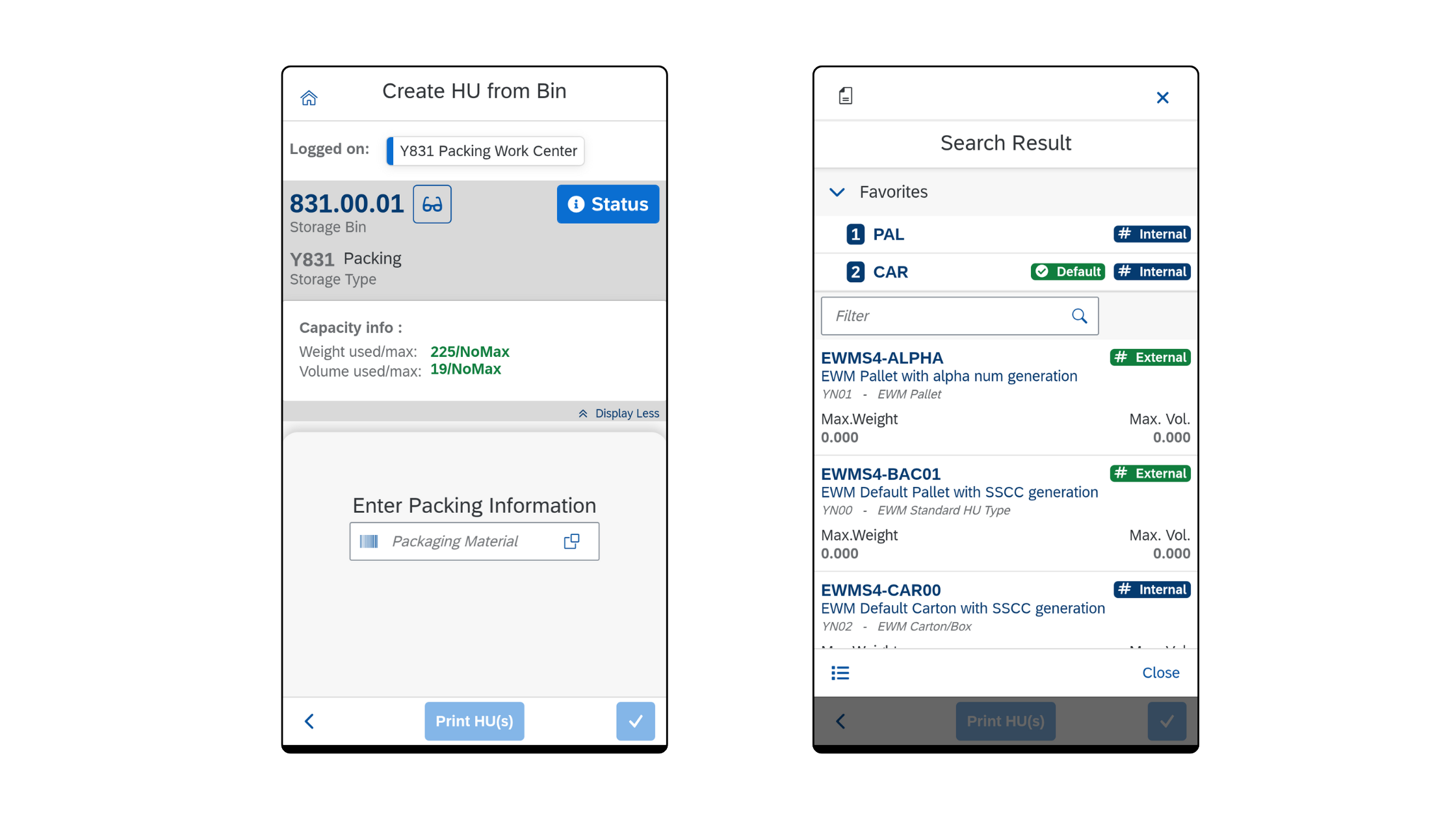

1. Extended favourite packaging materialsFavourite packaging materials are now available in more packing-related apps when the user is logged into a Work Center.

This allows faster packing, less searching and fewer clicks.

A future update will extend this capability to inbound delivery packing apps.

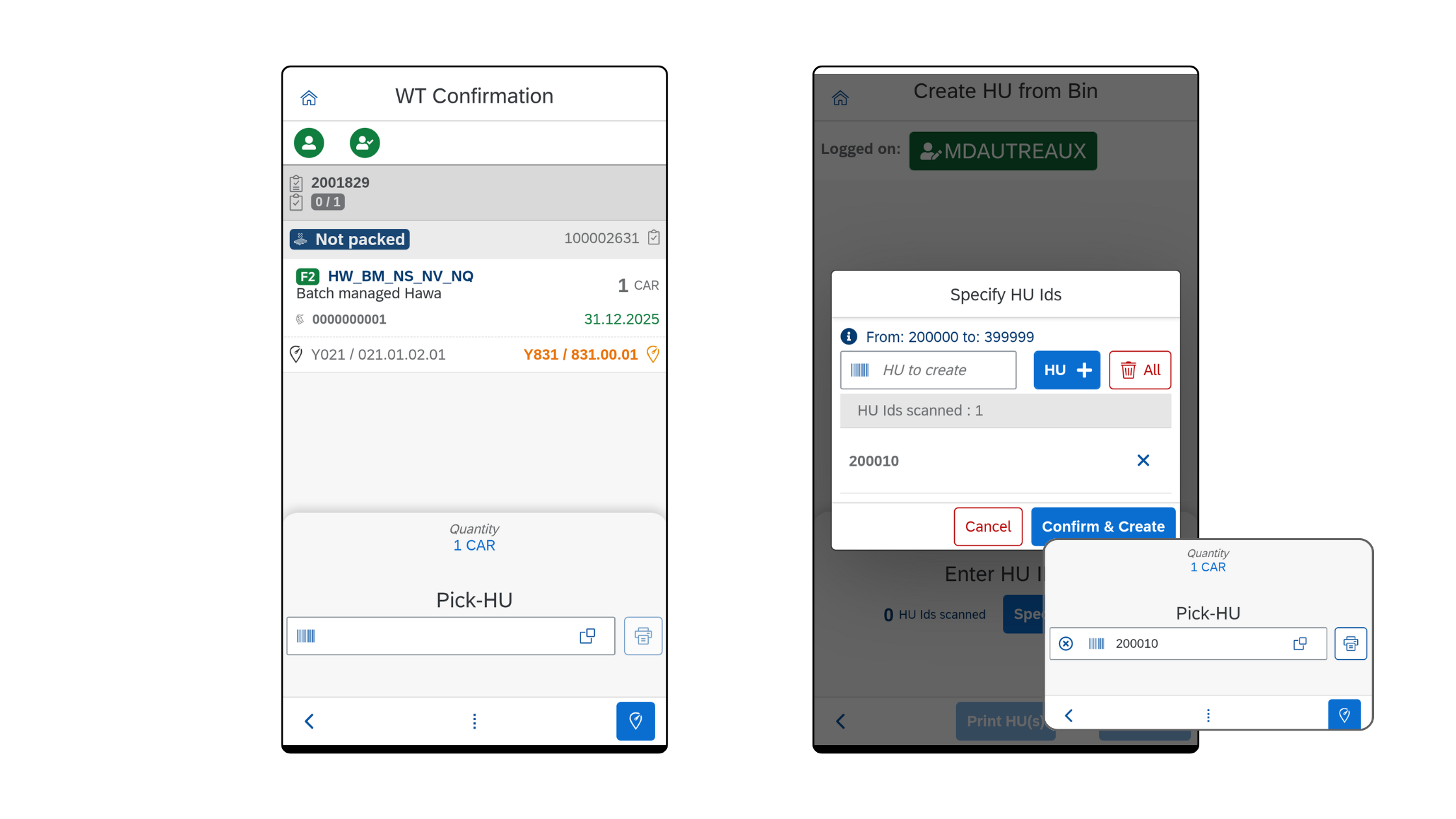

2. Faster Pick-HU creation using HU Planning

Previously, creating a Pick-HU from a planned HU required several successive steps: opening search help, selecting the planned HU, clicking “Create”, then navigating to the creation app.

With Calcium, operators start directly with the scan.

The application immediately recognises that the scanned HU is a planned HU and launches a shortened Pick-HU creation process.

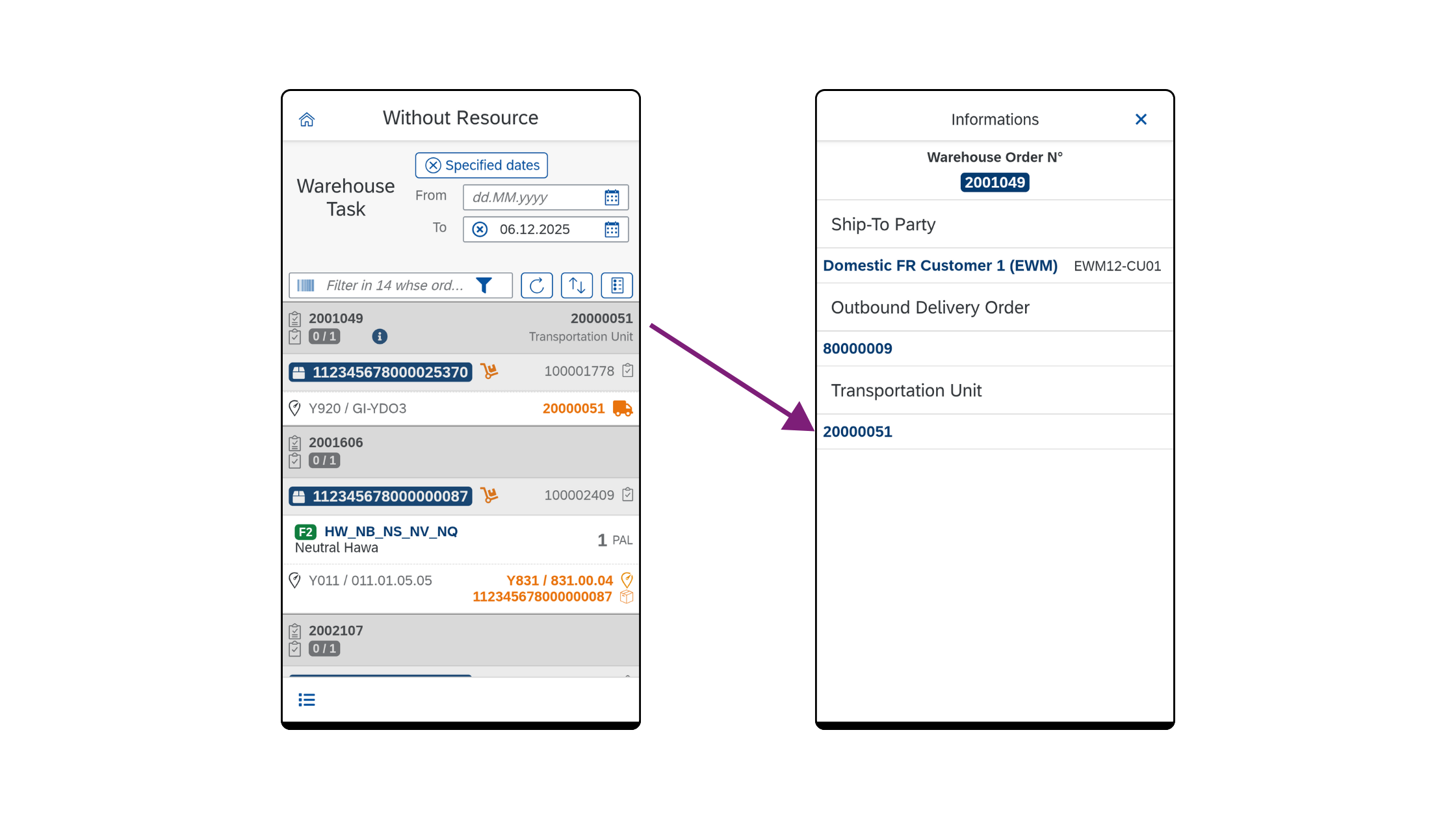

3. Customisable priority reference in Warehouse Orders

Every warehouse organizes activity around the most relevant information. Calcium now allows users to choose the primary reference displayed in Warehouse Orders, among:

Production order, outbound delivery order, ERP document (purchase or sales), ship-to, transportation unit or wave.

The worklist therefore highlights the information that truly matters to the warehouse team.

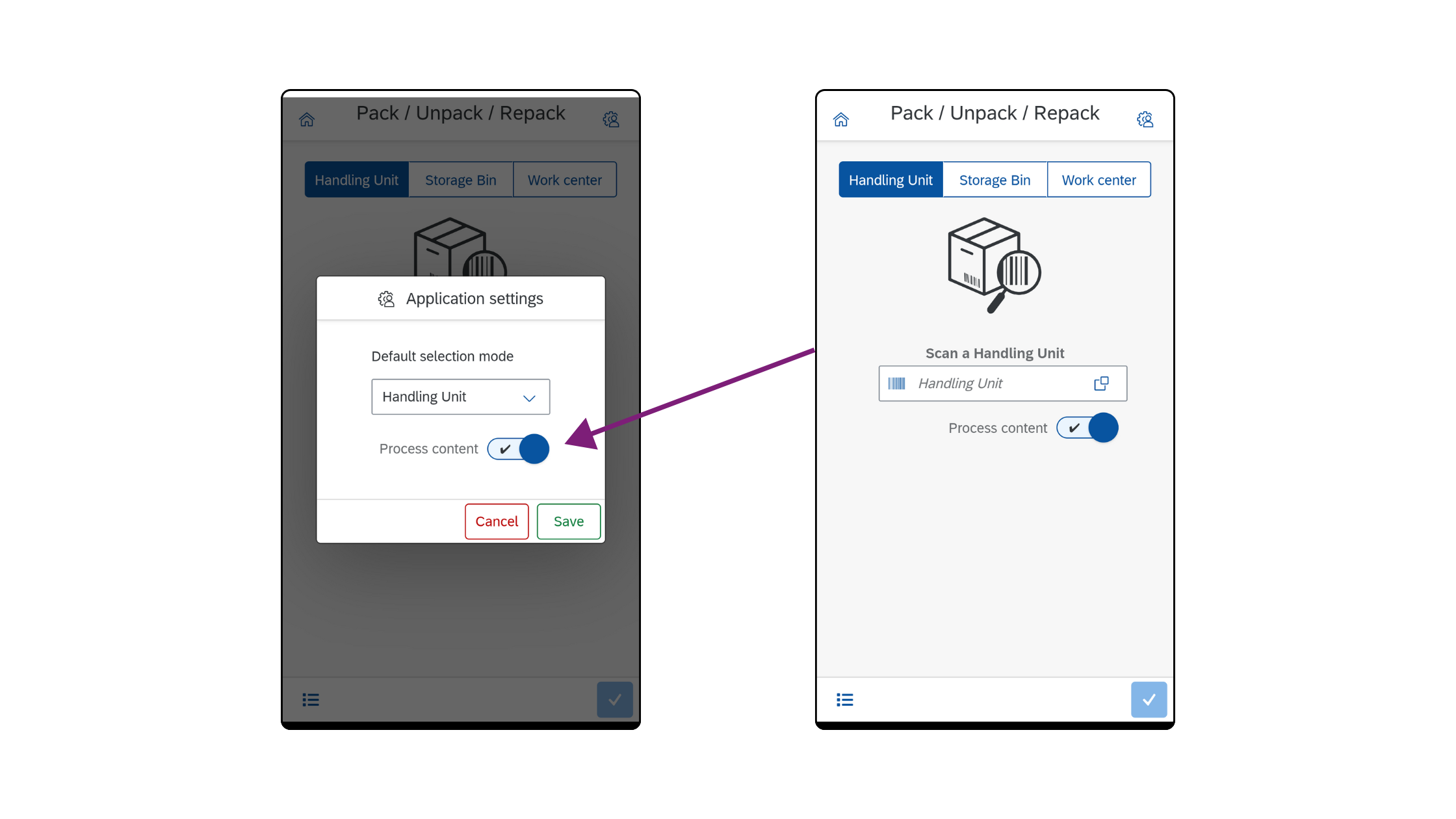

4. Pack Unpack Repack: “Process Content” available as default mode

In warehouses that never perform HU nesting, scanning a handling unit is primarily used to process its content. Calcium now allows users to activate Process Content as the default behaviour.

This is the fastest way to complete the operation without intermediate steps.

In one word, Calcium means reliability

This release strengthens productivity while above all reinforcing confidence in warehouse execution.- Less interruptions in execution

- Less scanning and putaway errors

- Less support investigation time

- EWM tasks that are faster, clearer and more consistent

Want to see our solutions in action?

Get in touch and ask for a personalized demo.